Delivery Valves: The Unsung Heroes of Fuel Injection

In the intricate world of internal combustion engines,

precision components play a vital role in ensuring smooth operation and optimal

performance. One such crucial element is the delivery valve, often referred to

as the Delphi valve due to the company's prominent contribution to this

technology. So buckle up, gearheads, as we delve into the fascinating world of

delivery valves and explore what makes Delphi valves stand out!

What is a Delivery Valve?

Imagine a tiny gatekeeper controlling the flow of a

pressurized liquid. That's essentially what a delivery valve does in

a fuel injection system. Located within the fuel pump, it receives pressurized

fuel and, based on engine demands, precisely regulates its delivery to the

injectors. This controlled release ensures efficient fuel atomization, optimal

combustion, and ultimately, smoother engine operation and better fuel economy.

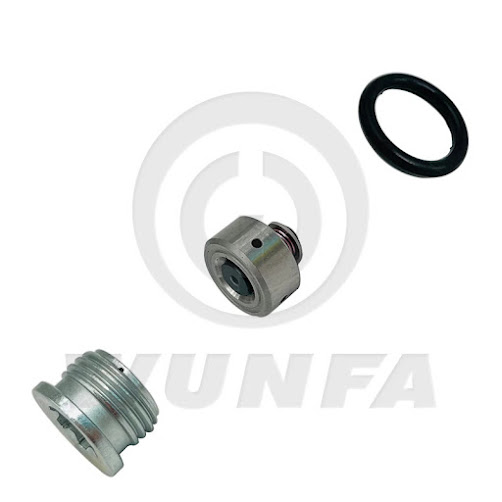

|

| Delivery valve |

Delphi's Legacy in Delivery Valve

Technology:

Delphi, a leading name in automotive technology, has a

long and distinguished history in developing and manufacturing high-performance

delivery valves. Their innovative designs and rigorous engineering have earned

them a reputation for reliability, durability, and precision. Here are some key

features that set Delphi valves apart:

Advanced Materials: Delphi utilizes cutting-edge

materials like hardened steel and ceramic components to withstand extreme

pressures and temperatures, ensuring consistent performance and extended

lifespan.

Precise Calibration: Each valve is meticulously

calibrated to deliver the exact amount of fuel required, optimizing engine

efficiency and minimizing emissions.

Wide Range of Applications: Delphi offers a diverse

range of valves compatible with various engines and fuel systems, catering to a

broad spectrum of automotive needs.

.jpg) |

| Delphi valve |

Benefits of Using Delphi Delivery Valves:

By choosing Delphi

valves, you gain several advantages:

Improved Engine Performance: Precise fuel delivery

translates to better fuel economy, smoother operation, and reduced emissions.

Enhanced Reliability: Durable construction ensures

long-lasting performance and minimizes the risk of breakdowns.

Reduced Maintenance Costs: The extended lifespan of Delphi

valves translates to lower maintenance costs in the long run.

Beyond the Basics:

Delphi's commitment to innovation extends beyond

simply manufacturing valves. They actively research and develop new

technologies like common rail injection systems, pushing the boundaries of fuel

efficiency and engine performance.

In Conclusion:

Delivery valves, often synonymous with Delphi's

expertise, play a crucial role in the smooth operation and efficiency of modern

engines. By understanding their function and appreciating the advancements made

by Delphi, we gain a deeper appreciation for the intricate dance of technology

that powers our vehicles. So, the next time you hear your engine purr, remember

the silent symphony of components like the delivery valve, ensuring optimal

performance under the hood!

Comments

Post a Comment